Q & A about Ring Pumps

Here, we answer typical questions that you may ask to Aquatech. If you have any questions about the Ring Pump, please refer to it.

Question

- What is the difference between a regular tube pump and the Ring Pump?

- Please tell me about the tube.

- Please tell me about the pulsation of the Ring Pump. (About discharge rate)

- Please tell me about the discharge/suction performance.

Answer

- What is the difference between a regular tube pump and the Ring Pump?

-

The Ring Pump was developed by Aquatech to extend the tube life of conventional tube pumps (roller pumps). For more information, please see the link below.

Comparison with conventional tube pump (roller pump).

- Please tell me about the tube.

-

An important part of the Ring Pump is the tube through which the liquid passes. You need to choose the right tube for the liquid you are using. Improper use of the tube can cause problems by causing the liquid to damage the tube and affect the life of the tube, or to elute the components of the tube into the liquid and change the components of the liquid.

If you provide the liquid to be used, we can conduct a liquid contact test using various tubes and select the tube based on the result. Please let us know.The main tubes used in our Ring Pumps are as follows.

Other tubes can be used depending on the liquid, so please contact us.Manufacturer Tube name Material Saint-Gobain K.K. PharMed BPT Thermoplastic elastomer Versilon

F-5500-A

(Formerly known as Fluran)Fluorine elastomer Tygon A-60-F (Formerly known as Norprene) Thermoplastic elastomer SWFT

(Suwa factory product)Thermoplastic elastomer Mitsuboshi Co., Ltd. Transmaster TM-15 Olefin-based ------------- Silicone tube Silicone rubber ❊PharMed, Versilon and Tygon are registered

trademarks of Saint-Gobain, France.

❊Transmaster is a registered trademark of

Mitsuboshi Co., Ltd.

- Please tell me about the pulsation of the Ring Pump. (About discharge rate)

-

When the flow rate (flow speed) of the discharged flow is not constant and increases or decreases periodically, it is called "flow is pulsating" or "pulsating flow".

The discharge flow of the Ring Pump has pulsation.

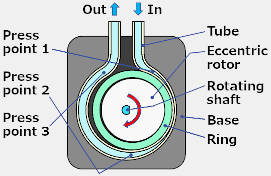

The Ring Pump discharges fluid by rotating the eccentric rotor and moving the press point of the tube. Between the press point 3 and the press point 1, the compression point moves from the discharge side to the suction side, and the discharge of the fluid is cut off.

At press point 3, the movement of the eccentric rotor removes pressure on the tube, causing the tube to expand and reduce internal pressure. Therefore, the pressure on the discharge side causes the fluid to flow back slightly from the discharge side.

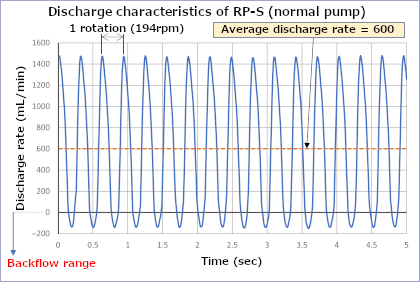

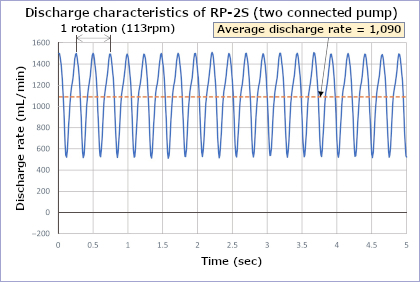

In this way, a general Ring Pump has a pulsation in which the discharge amount becomes negative (backflow) in one cycle for each rotation of the eccentric rotor.By using the two connected pump with press points shifted by 180 degrees, such as the RP-2S series and RP-2GⅡ series, the range of pulsation change can be reduced.

The table below shows a typical example of the relation between the time and the discharge rate of the RP-S series (normal pump) and RP-2S series (two connected pump). In the normal pump, the discharge amount has changed to the minus range. This part means that there is a backflow.❊The discharge rate in the catalog and

website is the average discharge rate in

the figure.

- Please tell me about the discharge/suction performance.

-

This website provides information on the suction performance and discharge performance of the pump using the PQ curve that shows the relation between the suction/discharge height and the discharge rate.

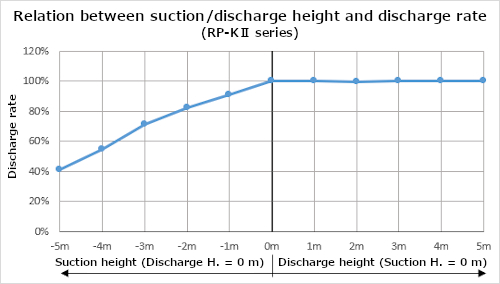

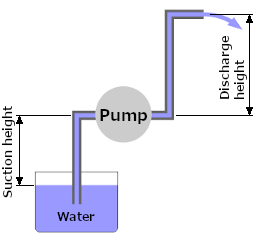

The figure below shows an example of the RP-KⅡ series P-Q curve and a explanation of the suction/discharge heights.

The suction height is the height from the surface of the water to be sucked to the pump.

The discharge height is the height from the pump to the discharge port when discharging into the air, and the height to the water surface when discharging into the water in the container.

In the P-Q curve the discharge amount is set to 100% when the suction height and the discharge height are

0 m, that is, the suction water surface, the discharge port, and the pump are set to the same height. Measure the rate of change in the discharge rate when the suction height is increased while the discharge height remains 0 m, and the rate of change in the discharge rate when the suction height is increased while the suction height remains 0 m. The P-Q curve combines those measurements in a single graph.

In the P-Q curve, the discharge amount decreases as the suction height increases, but the effect on the discharge amount is small even if the discharge height increases. The suction force depends on the elastic restoring force the tube. As the suction height increases, the force required to suck the water increases, so the amount of water sucked decreases. As a result, the discharge rate is also reduced.

Discharging is performed by sequentially squeezing the tubes with the power of a motor. Since there is a margin in the motor power, the discharge rate hardly changes at a height of about 5 m.

The curve changes depending on the model of the Ring Pump, but the Ring Pump has this tendency.

❊The discharge rate of catalogs and

websites is the discharge rate of water

when the suction height is 0 m and the

discharge height is 0 m.